Amazon.com: Texture and Anisotropy: Preferred Orientations in Polycrystals and their Effect on Materials Properties: 9780521794206: Kocks, U. F., Tomé, C. N., Wenk, H. -R., Mecking, H.: Books

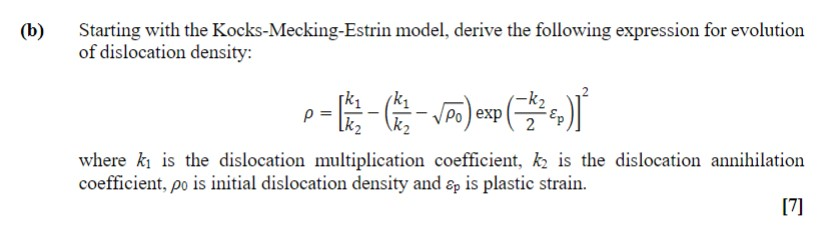

Revisited Storage and Dynamic Recovery of Dislocation Density Evolution Law: Toward a Generalized Kocks–Mecking Model of Strain‐Hardening - Bouaziz - 2012 - Advanced Engineering Materials - Wiley Online Library

Kocks-Mecking-Estrin strain hardening plot of Al alloys in the various... | Download Scientific Diagram

Kocks–Mecking plots The plots of strain hardening rate against true... | Download Scientific Diagram

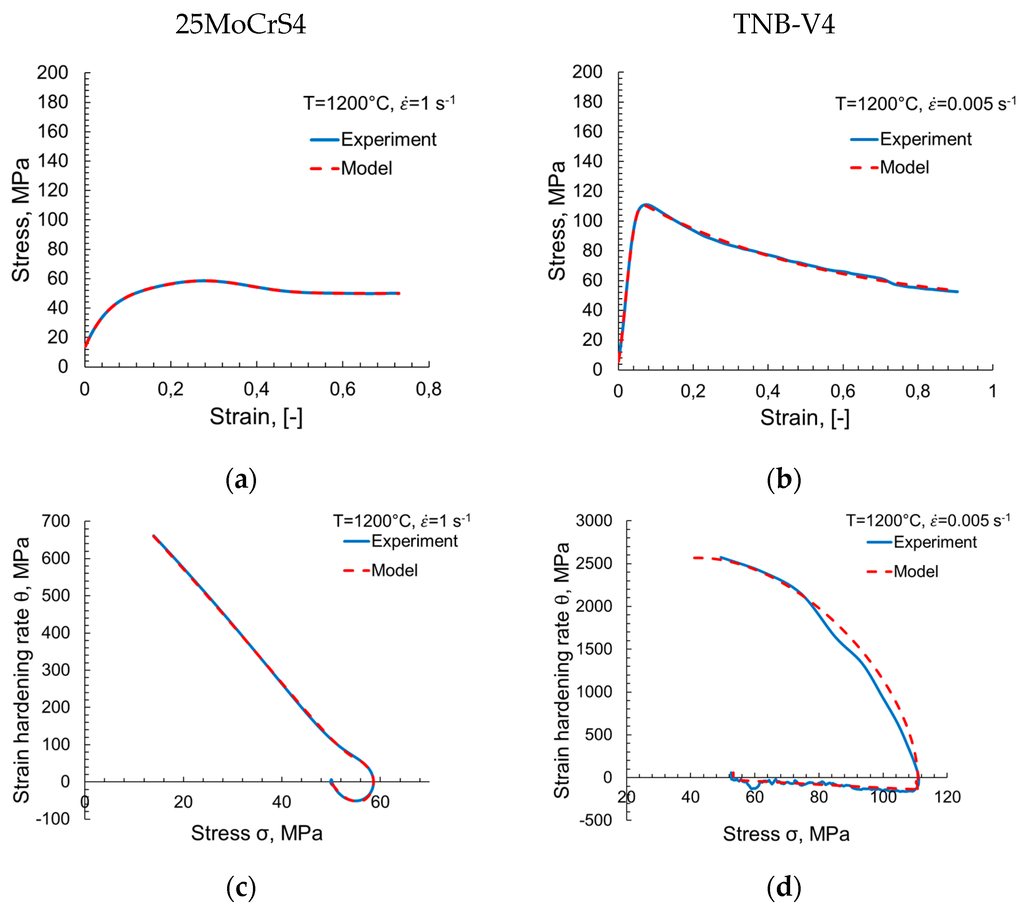

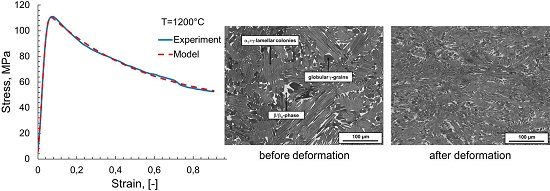

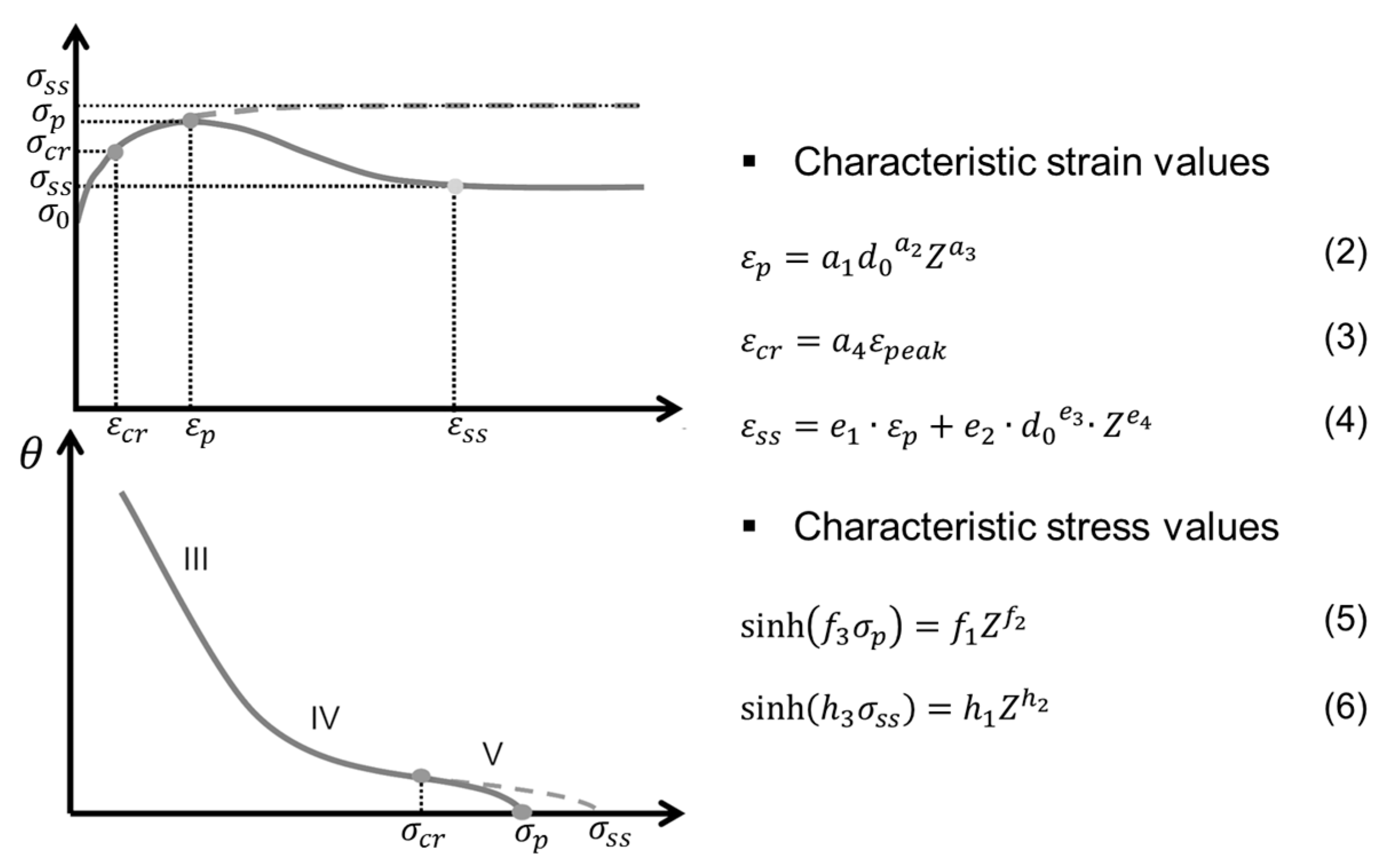

Metals | Free Full-Text | Devising Strain Hardening Models Using Kocks– Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel

Kocks-Mecking analysis of the size effects on the mechanical behavior of nickel polycrystals - ScienceDirect

Modified Kocks–Mecking–Estrin Model to Account Nonlinear Strain Hardening | Metallurgical and Materials Transactions A

Metals | Free Full-Text | Devising Strain Hardening Models Using Kocks– Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel

Kocks-Mecking analysis of the size effects on the mechanical behavior of nickel polycrystals - ScienceDirect

Modified Kocks–Mecking–Estrin Model to Account Nonlinear Strain Hardening | Metallurgical and Materials Transactions A

Kocks-Mecking analysis of the size effects on the mechanical behavior of nickel polycrystals - ScienceDirect

Influence of cluster hardening on strength and strain hardening behavior of various aluminum alloys - Nichteisenmetallurgie

Prediction of long-term creep behaviour of Grade 91 steel at 873 K in the framework of microstructure-based creep damage mechanics approach - J Christopher, BK Choudhary, 2019

![PDF] Devising Strain Hardening Models Using Kocks–Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel | Semantic Scholar PDF] Devising Strain Hardening Models Using Kocks–Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/07e0cad433f634e9f1ed5a010d450178aac17860/4-Figure1-1.png)

PDF] Devising Strain Hardening Models Using Kocks–Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel | Semantic Scholar

Metals | Free Full-Text | Devising Strain Hardening Models Using Kocks– Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel

![PDF] Devising Strain Hardening Models Using Kocks–Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel | Semantic Scholar PDF] Devising Strain Hardening Models Using Kocks–Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/07e0cad433f634e9f1ed5a010d450178aac17860/9-Table2-1.png)

PDF] Devising Strain Hardening Models Using Kocks–Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel | Semantic Scholar

A crystallographic dislocation model for describing hardening of polycrystals during strain path changes. Application to low car